The relationship between quality and productivity in the production. In Production, there are two important things that are most often discuss. The second thing is the quality and Productivity.

- So what is meant by quality and productivity?

- What is the relationship between quality and productivity?

In this article discussing, why the company is oblige to improve the quality and the same time (simultaneous) in the production process.

Quality and Productivity

Quality (Quality) or quality is a product that is produce in accordance with specifications for compliance to the needs. Basically, the quality is very high. Quality (Quality) surely is not just a product or merchandise, but also a service sector or service.

Productivity (Productivity) is a ratio or comparison between the INPUT (Input) and OUTPUT (output) in the activity results in a product or service. The basic productivity is a measure of efficiency of production activities. For more details regarding discussion of productivity, you can read this article: calculate the work productivity in production.

Levels of Management

After companies determine customer needs, they must concentrate on meeting those needs by yielding high quality products at an efficient rate. Companies can improve quality and productivity by securing the commitments of all three levels of management and employees as follows:

- Top‐level management: Implement sound management practices, use research and development effectively, adopt modern manufacturing techniques, and improve time management.

- Middle management: Plan and coordinate quality and productivity efforts.

- Low‐level management: Work with employees to improve productivity through acceptance of change, commitment to quality, and continually improving all facets of their work.

Productivity is the relationship between a given amount of output and the amount of input need to produce it. Profitability results when money is left over from sales after costs are paid. The expenditures made to ensure that the product or service meets quality specifications affect the final or overall cost of the products and/or services involve.

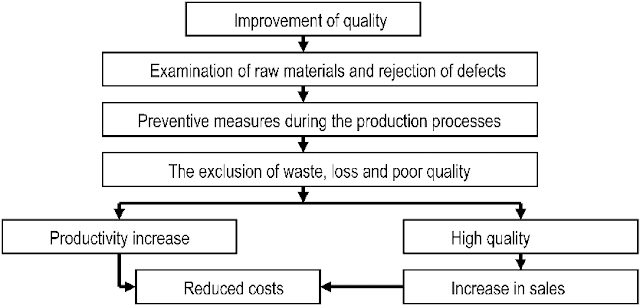

The relationship of quality and Productivity

Basically, the main purpose of a business is to make a profit or not. To increase the company's profit or advantage, the simplest and most first ideas or proposals appear was to improve productivity. It is not always appropriate.

The following example picture of why improving productivity is not the appropriate option on certain conditions.

Example:

The company "X" is an electronics manufacturing company. That produces DVD Player, every day the company produces as much as 1000 units with an average level of defective (disable) is 5%. To increase Profit, the company management decide to increase productivity by up to 10%. Which means that every day the company must produce the 1100 units.

The decision increases the Productivity by adding a number of Production Outputs makes. It the company's employees pressure (stress) and fear. But because it is a policy and instructions from the management, the employees are still trying to fulfill them.

However, the level of damage cause by the product can increase from the previous average of 5% per day. To an average of 12% per day. This means that every day there are 132 units (corrupt). Even and good products that are ready to be ship to the customer is just 968 units only. The numbers are only slightly higher 18 units or more of the previous condition (950 units).

Analysis

Increase productivity will not be accompanied by process control and improvement. The degree of damage will be higher so that the result is often not expect by a management company.

On the other hand, it will always be able to produce an increase in productivity. For example, the "Y" Company produces 1000 units of DVD players per day with an average level of defective (damage) is 5%. This means that each day. There were 50 units of handicap and 950 units both ready to be sent to the Customer. The management of the company is always striving to improve quality.

Review

According to the management company "Y", the rate of defective (damage) that reaches 5% it is a cost that needs to be avoid. When process control can be improve, a number will increase so that it can generate profits for his company.

For greater clarity, the following calculations are base on the example above:

The Company "X"

| Before a request to raise 10% Productivity | After a request to raise the productivity of 10% | |

| The Rate Of Defective (Disabled) | 5% | 12% |

| The number of produced | 1000 | 1100 |

| The number of Defective (disabled) | 50 | 132 |

| A good amount of (GOOD) | 950 | 968 |

The Company "Y"

| Before Improving The Quality | After Improving The Quality | |

| The Rate Of Defective (Disable) | 5% | 2% |

| The number of produce | 1000 | 1000 |

| The number of Defective (disable) | 50 | 20 |

| A good amount of (GOOD) | 950 | 980 |

Let's see the difference on the results of the company "X" and "Y". The company "Y" was instruct to add 10% Productivity instead of generating the amount of output. Both were lower than the company "Y" which improves its quality.

Conclusion

The example above is only an overview of how quality improvements can affect productivity in production.

Management of the company should be able to find a way to balance the increase in quality and productivity. Too stress the increase productivity will sacrifice quality which ultimately will also lower production output.

While the quality of productivity will be improve, it will also give rise to high operating costs. Therefore, it has improve quality and productivity without compromising one of them.

The company will enjoy advantages such as cost of goods Production is lower, reducing the cost of repeat jobs (rework costs), improving customer satisfaction (Customer Satisfaction) and surely achieving Profit (Profit) .

No comments:

Post a Comment