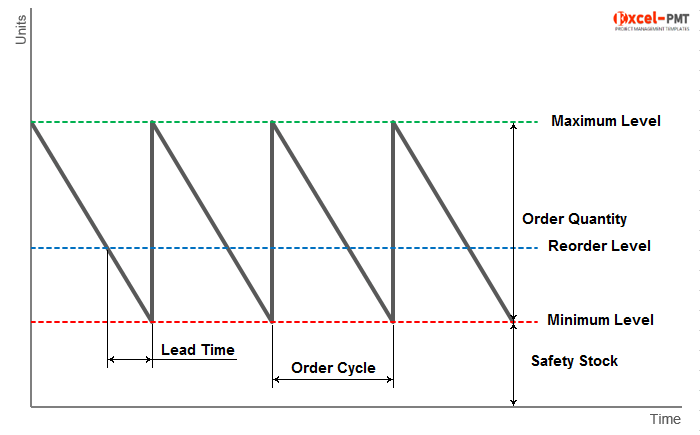

A reorder point in a company is very important, because it means paying attention to reorder again says the reorder point is the moment where preparation done again.

If the grace period between when the company order and the item came is commonly call lead time equals zero, then at the moment the number of inventories equal to zero by the time that's done.

That is the reorder point is the point at which moment or should be held similar reservations, so arrival or receipt of materials order it at exactly the right time where inventory top safety stock is equal to zero.

Thus, the expect influx of materials order will not pass through time so that it will violate the safety stock. When an order is done after passing the reorder point, then the material request will be accept after the company was force to take material from the safety stock.

With the determination/reorder point assignment note factors, as follows:

Procurement lead time

The Procurement lead time, namely the use of the material during the grace period gets the goods.

The magnitude of the safety stock, meant in the sense of "procurement lead time" is the time in which includes the start of efforts require to order the goods until the goods/materials receive and place in the warehouse the assignment.

Reorder point can be define in various ways, among others:

Set the number of usage during the "lead time" plus a certain percentage, for example, establish that the safety stock amounting to 50% of usage during the "lead time" is 5 weeks, whereas the needs of material each week is 40,

Then the Units Reorder point = (5 x 40) + 50% (5 x 40) = (100 + 200) = 300 units.

By setting the use during the "lead time" and coupled with the use of a particular period as safety stock.

For example the need for 4 weeks.

Then Reorder Point = (5 x 40) + (4 x 40) = 200 + 160 = 360 units.

When a new order is carry out after the high inventory 300 units this means. That at the moment the order goods came by. The company had to already taking material from the safety stock amounting to $ 60 units. At the time the goods are book in the warehouse supplies come live 100 units (i.e. 300-200). Whereas safety stock is set of 100 units.

No comments:

Post a Comment